MATERIALS/TOOLS NEEDED

1) Shingle Hatcher - or Hammer. Pnuematic hammers that are cushioned to seat the nail, rather than drive it, are acceptable.

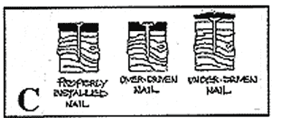

2) Nails - 11 ga or 6 d 1/2" flat head galvanized, stainless steel or copper roofing nails with wide flat heads of sufficient length (2 x thickness + 1") to penetrate the sheathing the full thickness and/or the overlapping shingles. Nails should be driven flush with the surface, but not over driven. See diagram C.

3) Diamond blade saw is needed to cut custom fit shingles.

4) Elastic cement needed to glue hip and ridge, should be waterproof, heat resistant and freeze resistant.

5) Silicone sealer if desired to seal hip/ridge.